#35 Gearing and Sprocket Sizing

#35 Gearing and Sprocket Sizing

Looking for #35 sprockets and chains with free delivery? You can find them here: http://www.cutpriceracing.com.au/store/35-Pitch-Sprockets/

Bought a #35 sprockets and can't get it to align properly? Find the fix here: SPR##5S Aligning #35 Split Sprockets

GUIDE - PROJECT GEARING SELECTION

[/color]

GEARING UP

#35 Gearing Explained

INTRODUCTION - About this guide

You can also read this guide on our website by clicking here.

When customers choose #35 pitch gearing (which we highly recommend for projects due to the 2-piece split sprockets and removable link chains – see our chain guide for more information) I am often asked the question “What is the inside diameter of your split sprocket?” and “What is the outside diameter of an x tooth sprocket” so I’ve decided to write this informative but straight-forward guide focussed on explaining what needs to be done to fit our standard race kart sprockets and gearing your project.

Generally, when gearing your project, you have 3 problems to overcome.

1.

Fitting the sprocket to your axle

2.

Ensuring the overall sprocket size does not foul on the ground or chassis

3.

Selecting a practical starting gear ratio

This guide will run you through the decision making process as well as provide technical details on the products so that you can decide if #35 race kart gearing is suitable for your project. I’ll run through these three sections quickly but informatively in the hope I don’t bore you, but that you have easy access to the information needed to get it right the first time.

PART 1 - Fitting the sprocket to your axle

Our #35 sprockets are a split sprocket which is ideal in situations where the sprocket is driven ‘inboard’ on the axle (ie: between the axle bearings). They are easy to remove and install making gearing a breeze to get correct, or to change out a worn sprocket.

You can find our full range here: http://www.cutpriceracing.com.au/store/home.php?cat=351

The centre bore size A is 116mm.

The PCD Diameter(B) is (6x) 132mm (centre of 6mm holes on opposite sides of sprocket)

Bolt hole to adjacent bolt hole centre (dimension not shown) ~ 67mm

![]()

All standard race-kart sprocket hubs will accept our sprockets. We can supply sprocket hubs to fit most metric shaft sizes – 25mm, 30mm, 35mm, 40mm.

You can find sprocket hubs to suit here (Click your axle size and keyway width to find your hub):

25mm/6mm, 30mm/6mm, 30mm/8mm, 35mm/6mm, 35mm/8mm, 40mm/8mm

The hubs will accept the sprocket perfectly. All you need to do is slide it onto your shaft. Select the correct size shaft version of the sprocket. If you have an imperial size shaft, we cannot offer a solution, but some people have successfully adapted the metric hubs to an imperial shaft.

PART 2 – Ensuring the overall sprocket size does not foul on the ground or chassis

Your new #35 sprocket will differ in sizing depending on the number of teeth you have chosen. Circumference will determine the number of teeth you will have. The reason the size differs is because the pitch of the chain determines the length required for one full link or tooth.

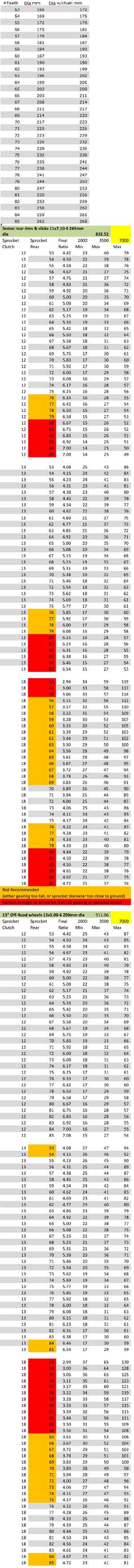

For those uninterested in the math, please skip this paragraph. #35 pitch is 9.525mm, so for every tooth, the circumference must be increased by 9.525mm. In addition, the height of each tooth is about 5mm so we need to add approximately 2.5mm extra from the centreline of each tooth (or approximately 5mm to the diameter) This means we have a formula #TEETH x 9.525mm = Pi x Diameter. Or we could write it as #teeth x 9.525mm divided by Pi = Diameter plus 5mm. Translating back to diameter, our smallest sprocket (53T) has a diameter of 53 x 9.525 / Pi (3.141592) = 166mm.

Your chain will sit around 3mm proud of the tip of each tooth, so you’ll need to add approximately 6mm to the diameter of the sprocket to get the correct clearance amount.

See table of diameters below.

PART 3 – Selecting a practical gear ratio

Once you’ve determined your limitations in relation to ground and chassis clearances, the next step is to determine the best gear ratio. There are several things to consider, including:

- Desired Acceleration

- Desired Top Speed

- Minimum operating speed

o One of the most important considerations is the minimum ‘fully engaged’ clutch speed. Most stock clutches engage around 2000rpm. With a governed 4-stroke engine, that means you have a working range of somewhere between 2000 and 3500rpm. If you select too tall gearing, and you constantly operate the kart at speeds which bring the motor close to or below the 2000rpm engagement point, you will encounter clutch problems as the clutch is continually slipping.

The following table gives approximate speeds for gearing. It is recommended not to use gearing in the orange sections, and red sections will almost certainly result in mechanical failure.

Tall gearing (lower ratios) may struggle to gain rpm if the power of the engine is not enough to overcome the torque of the axle. This is more pronounced the larger the wheels are, so bear this in mind.

Always select the shortest gearing (highest ratio) first and work your way down with rear sprocket sizing to ensure you do not damage your clutch and that you can ensure your project will get mobile initially.